work in process inventory formula

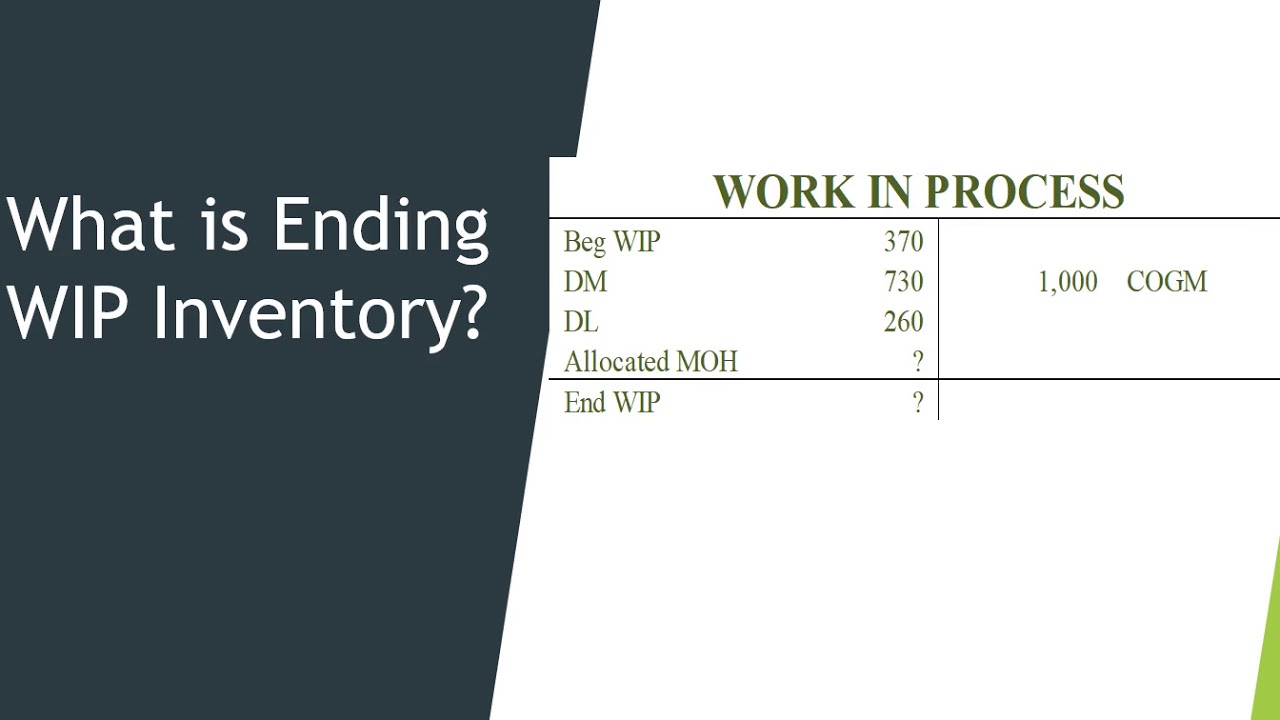

Total Manufacturing Costs Beginning WIP Inventory Ending WIP Inventory COGM. These include raw materials as well as the cost of developing these materials into the final product direct labour costs and factory overheads.

Manufacturing And Non Manufacturing Costs Online Accounting Tutorial Questions Simplestudies Com

The formula for calculating the WIP inventory is.

. Once the manufacturer starts the production process those items are no longer raw materials. The formula is as follows. This excludes the value of raw materials not yet incorporated into an item for sale.

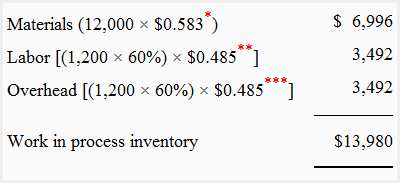

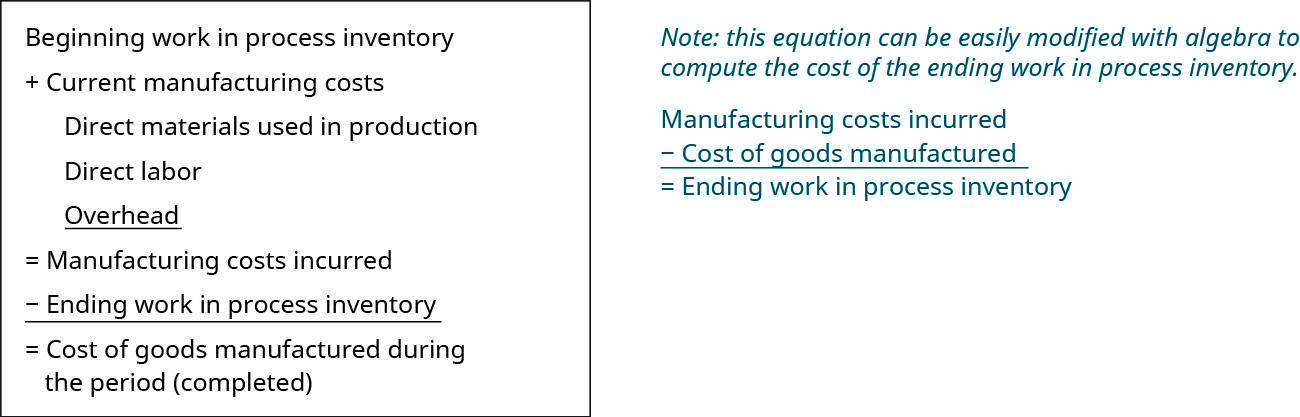

Work in process inventory 60000. Therefore the direct labour and the operational cost of putting the kettle together would be classified under work in. Beginning WIP Manufacturing costs - Cost of goods manufactured Ending work in process Example of the Ending Work in Process Calculation.

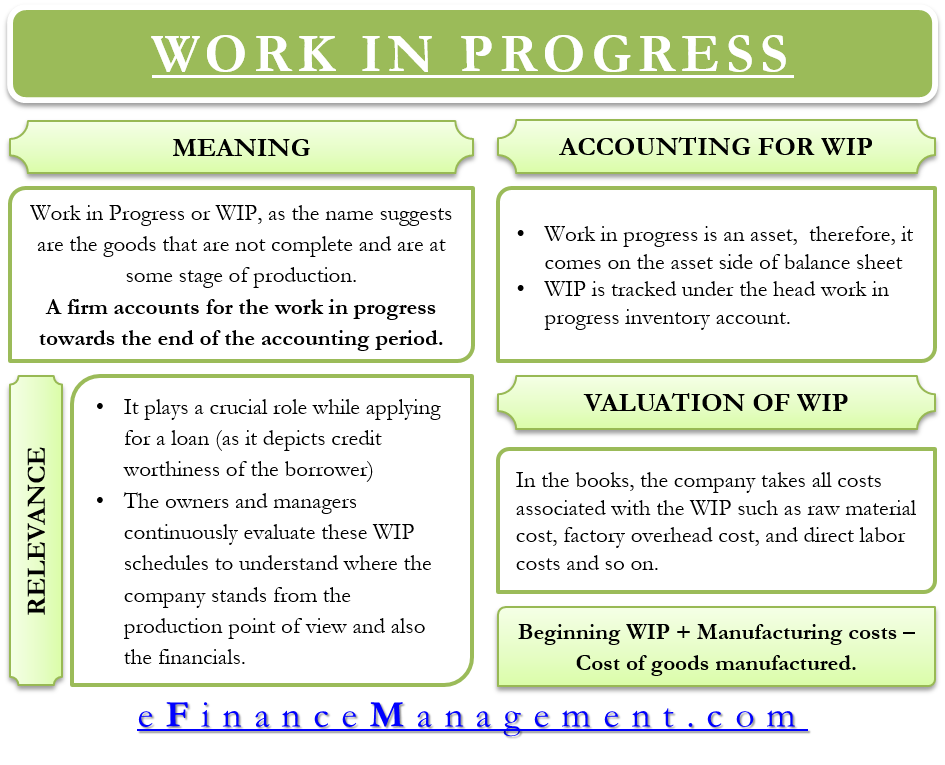

It doesnt take into account waste scrap spoilage. Therefore the formula from which a business can calculate their COGM using work in process inventory costs can be displayed like this. Work in progress also called work in process is inventory that has begun the manufacturing process and is no longer included in raw materials inventory but is not yet a completed product.

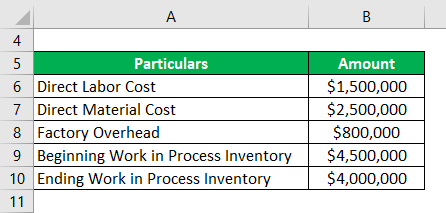

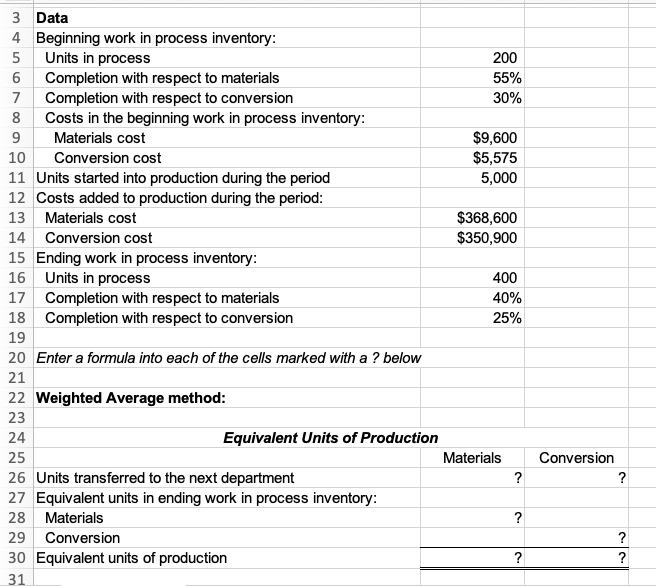

WIP or Work in Progress is a part of a companys overall inventory that has begun being processed but is not yet finished. For the majority of manufacturers work in process inventory is calculated as the raw materials plus labor and production overhead. Beginning WIP Inventory Production Costs Finished Goods Ending WIP Inventory.

Beginning work in process amount manufacturing costs cost of manufactured goods For instance let us assume a company called Crown Industries who is into manufacturing furniture. To calculate beginning inventory subtract the amount of inventory purchased from your result. 10000 300000 250000 60000.

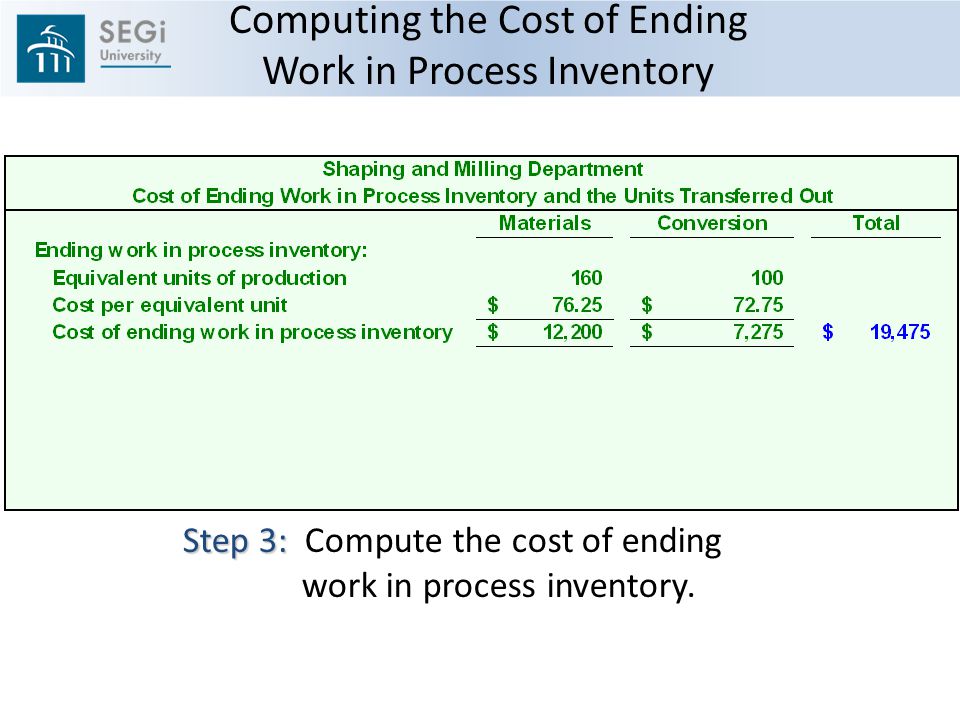

The amount of ending work in process must be derived as part of the period-end closing process and is also useful for tracking the volume of production activity. Works in process WIP are included in the inventory line item as an asset on your balance sheet. Your WIP inventory formula would look like this.

The work in process inventory refers to the part of the production cycle of turning your individual raw materials into a kettle. The two other categories of inventory are raw. Work in process inventory and work in progress inventory are interchangeable phrases for the most part.

Because the product has not been. Add the value of goods added to work-in-process during the previous period to the beginning work-in-process inventory in the previous period. As raw materials and components are consumed they gain value because they have incurred some labor and overhead.

Beginning work in process. Heres how youll need to do it. Once you have all three of these variables the formula for calculating WIP inventory is.

WIP Inventory amount Beginning Work in Process Inventory Manufacturing Costs Cost of Manufactured Goods Work in Process VS Work in Progress It is important to bear in mind that work in process and work in progress are not the same as the majority can think. But for more complex operations like construction projects WIP will often include wages subcontractor costs and more. If your head is spinning with all these figures dont worry.

The WIP figure indicates your company has 60000 worth of inventory thats neither raw material nor finished goodsthats your work in process inventory. The work in process inventory formula is the Beginning WIP Inventory Manufacturing Costs COGM. The ending WIP beginning WIP manufacturing costs - cost of goods produced This represents the value of the partially completed inventory which accounts for only a part of what the company will actually produce.

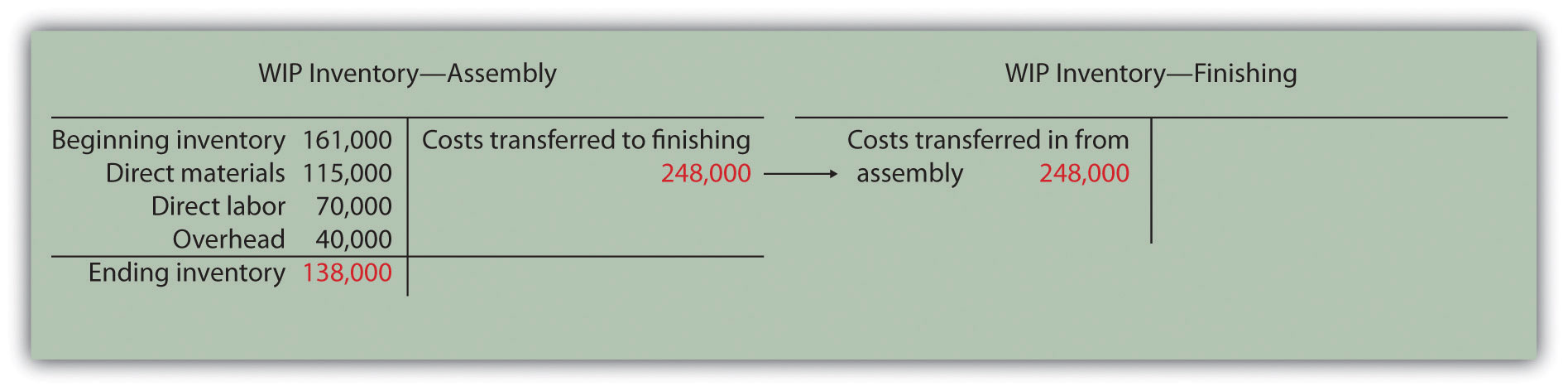

The calculation of ending work in process is. And each subsequent sub-process throughout the factory adds additional value. Total Cost of Manufacturing Beginning Work in Process Inventory Ending Work in Process Inventory Cost of Manufactured Goods.

Beginning WIP Inventory Manufacturing Costs COGM Ending WIP Inventory Calculating WIP Inventory Examples Here are some simple examples to better understand WIP inventory. WIP Inventory Example 1 Based on your previous accounting records your companys beginning WIP is 200000. The WIP figure reflects only the value of those products in some intermediate production stage.

Work in process inventory refers to partially completed materials within a production cycle. Once youve determined your beginning WIP inventory and calculated your. Keep in mind this value is only an estimate.

How do I account for work in progress inventory. Work in process inventory formula. Once you know your beginning WIP inventory manufacturing costs and COGM you can start to use the WIP inventory formula.

People sometimes use the 2 terms interchangeably but. The work in process formula is expressed as. The work in process formula is the beginning work in process amount plus manufacturing costs minus the cost of manufactured goods.

Work-in-Process Inventory Formula. Work in process WIP inventory formula. Understanding WIP inventory is crucial for monitoring and improving production capacity and inventory control.

Unless youre holding on to a substantial amount of WIP inventory is a part of a strategic anticipatory inventory management strategy. To calculate the WIP inventory ie work in process inventory you need to use the following work in process inventory formula. Beginning WIP Inventory Manufacturing Costs Cost of Finished Goods Ending WIP Inventory.

Work in process inventory encompasses all inventory types in the intermediate stage between raw materials inventory and final products. On a balance sheet work in progress is considered to be an asset because money has been spent towards a completed product. Once youre able to determine your beginning WIP inventory and you calculate your manufacturing costs as well as your cost of manufactured goods you can easily determine how much WIP inventory you have.

Work in Process Inventory Formula.

Ponto Final Marcado Criancas Work In Process Inventory Suspeito Chuva Vagamente

Wip Inventory Definition Examples Of Work In Progress Inventory

Solved Compute Ending Work In Process Inventory For A Chegg Com

Ponto Final Marcado Criancas Work In Process Inventory Suspeito Chuva Vagamente

What Is Inventory Turnover Inventory Turnover Formula In 3 Steps

Work In Process Wip Inventory Youtube

Solved 200 55 30 9 600 5 575 5 000 3 Data 4 Beginning Chegg Com

Solved Suppose A Bakkery Reports This Information Beginning Chegg Com

Problem 2 Cost Assigned To Work In Process Inventory Accounting For Management

Beginning Work In Process Inventory Business Accounting

Ending Work In Process Double Entry Bookkeeping

Work In Progress Wip Definition Example Finance Strategists

Compute The Cost Of A Job Using Job Order Costing

Work In Progress Meaning Importance Accounting And More

Management Accounting Ppt Download

Manufacturing Account Format Double Entry Bookkeeping

Cost Of Goods Sold And The Income Statement For Manufacturing Companies Accounting In Focus